|

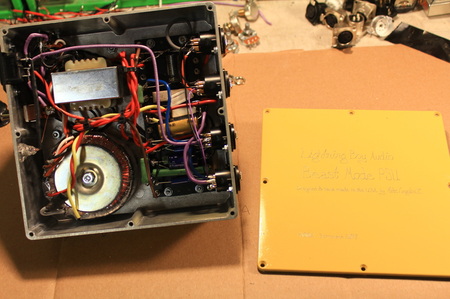

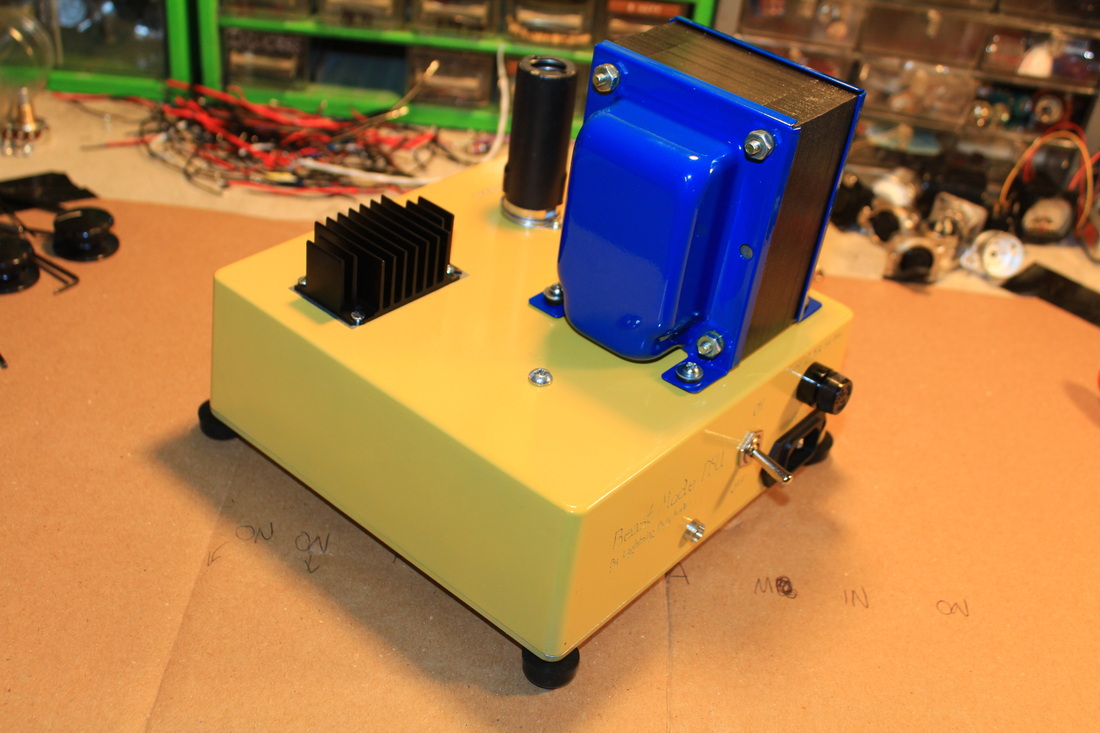

I started the build process with the most important element first. The power supply. The power supply is responsible for far more than just mere power. Its generally the largest source of noise, a major source of headroom, and a significant factor in the origins of punchiness. Therefore, in order to make a great power supply, great care and skill has to go into its design. Ladies, Gentlemen, and Rough Folk, I'm proud to share with you the first production model of The Beast Mode Power Supply Unit. Please forgive my novice photography at the bench (unofficial photos). The Beat Mode PSU is the power supply for Trinity (October 2015) and can power up to two Trinity units. It will also very likely continue on to use for future products. This is a hybrid sort of power supply since it has both solid state and vacuum tube technology onboard. The vacuum tube seen in the above photo is actually a thermal relay tube, which controls a time-delayed soft-start for the tubes on any Trinity connected. You can think of this as an automatic standby switch. Also seen in the photo is large heat sink. This is for cooling the linear voltage regulator below it. That regulator is related to the heater filament power for Trinity's vacuum tubes. It keeps it at a very stable DC voltage for superior low noise performance. The massive blue power transformer is one of 3 onboard. The other two transformers are internally mounted. This thing is really over the top in such a good way. All point to point wired. Thick high quality wiring for maximum current delivery. Big wattage resistors for low thermal noise. Low ESR, long-life electrolytic caps. Separate power transformers for each section of power: B+, Filaments, Phantom Power. The Beast Mode PSU is a heavy weight contender (it weighs a lot), but it is not the entire power supply for Trinity. Onboard each Trinity is the voltage regulation circuitry for the B+ section of the power supply associated with that particular Trinity Unit, so that each connected Trinity will have its own separate B+ supply. The regulators onboard Trinity are not solid state, they are inert gas VR tubes. In fact, nothing onboard Trinity is solid state. That definitely means the audio path is 100% pure vacuum tube heaven. And, ultra-low noise, of course.

Now that I have a working prototype the next step is building a production model. I have actually been working on this for about 4 days now. I don't like to think about this stage like prototyping, but it kind of is in a way. First step was plotting out the layout of the front and back panel components. The front panel controls needed to make sense in their layout, but also had to make sense with respect to the internal wiring. Shorter wires are always a plus, but not always the answer. The back panel layout has all the sensitive electronics; tubes, transformers, in/out connections. By sensitive I specifically mean in regards to susceptibility to electromagnetic interference and the transmission of such fields between channels. The back panel components had to be laid out in such a way as to minimize the effects of EMI to the greatest degree. After getting everything plotted I machined out the first production chassis and power supply. This stage of the game is where looks really matter. I wanted to go with a color scheme that reflected the Lightning Boy logo. Unfortunately, I was unable to find Lightning Boy yellow in my normal brand of paint. I did, however, find it in a different brand. Big freaking mistake. I painted the power supply and etched it. Looks great - no problems. Clear coated it and baked it. Done. Moving on... I painted the chassis, but when I started to etch it the paint began to flake away. WTF? Okay, maybe I messed up something when I painted it. Stripped it and tried again. Continued etching. Paint flaked off again and looks terrible. Its that damn paint! The chassis is not even salvageable. The paint was not adhering to the steel chassis, but strangely it adhered to the aluminum power supply. Ok, chalk this up as a loss and a learning experience. Back to machine work. I machined out a second chassis, but this time I found Lightning Boy yellow in the brand of paint I normally use! Yes! Had to do some serious hunting, but I have a source now. Got her painted and its currently drying. I'll etch it on Monday. I'm expecting it to work out really well. This paint brand has never failed me. More to come...

|

Details

About the AuthorMike Congilosi II, Owner/Designer/Electronics Engineer at Lightning Boy Audio and Owner/Audio Engineer/Music Producer at LBA Studios. Archives

July 2025

Categories |

RSS Feed

RSS Feed